Multi Process Robotic Cell

Introduction

Multi Process Robotic Cell demonstrates a flexible manufacturing cell. This cell is an assembly line where components of a main part gets assembled, the main part comprises of minimum of 7 sub-parts and more, which are then assembled by placing, inserting and part-screwing the main part. It has multiple stations which performs operation on the parts (like valve body assembly, vision inspection, testing, packaging). The main feature of the cell is exhibited using the programming, control and diagnosis of the robotic manipulator amongst other peripheral and safety devices. We call it as Multi Process robotic cell because it can be used for more than one manufacturing process.

There are different stations in the robotic cell:

1. Conveyor Station: Use to transfer the inventory tray or pallet to the place where robot can pick them.

2. Assembly Station: All the parts (axisymmetric and prismatic parts) will be assembled and screwed on the valve body in this station. Along with that inventory scanning and vision inspection of the valve bodies will be done.

3.Testing Station: All the pneumatic ports of the valve body will be tested in this station. If there is any leakage, valve body will be rejected.

4. Hex-nut Assembly Station:- Hex nut will be assembled on the body in this station.

5. Packaging Station: Assembled valve bodies will be placed in a box and packaging is done. A printing head will print the required details( type of bodies, number of bodies, date of assembly etc) on the box and then the box will be dispatched.

2. Assembly Station: All the parts (axisymmetric and prismatic parts) will be assembled and screwed on the valve body in this station. Along with that inventory scanning and vision inspection of the valve bodies will be done.

3.Testing Station: All the pneumatic ports of the valve body will be tested in this station. If there is any leakage, valve body will be rejected.

4. Hex-nut Assembly Station:- Hex nut will be assembled on the body in this station.

5. Packaging Station: Assembled valve bodies will be placed in a box and packaging is done. A printing head will print the required details( type of bodies, number of bodies, date of assembly etc) on the box and then the box will be dispatched.

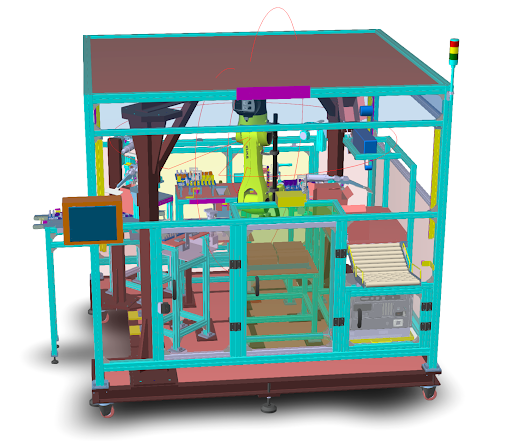

Physical System

CAD View

Video Description

The video here demonstrates the standalone function of loading inventory using trays from conveyor station to assembly station. The tray has multiple arrays of different sized part but same variety. There are trays with 3/2, 5/2, 5/2 double solenoid, 5/3 solenoid valve body. The end-effector of the robot have more than one tool attachments. This is possible due to tool changer allowing robot to perform multiple actions like pick and place, part screwing, gripping via vacuum suction cup, bar code part scanning.

Multi Process Robotic Cell

Services

Training

Site Integration

Simulation & Testing

Prototyping

Contact us today for implementing

"Smart Manufacturing"

Call us for any query

011-26582053, 8076197190