Smart Manufacturing Training Kits

Introduction

-

PLC Programming, Network Protocols

-

HMI Designing

-

Data Logging

-

Dashboard Designing, NodeRed

-

IIOT gateways and platforms

-

Augmented Reality

-

Machine Learning

-

Smart Sensing

-

Motion configuration and programming

-

Vision System

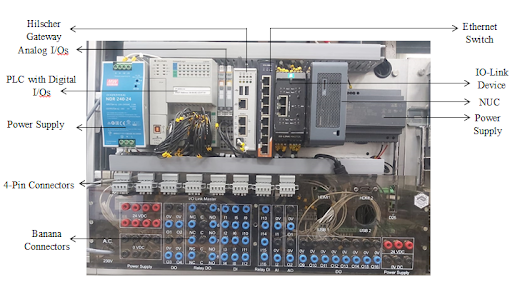

1. PLC Trainer Kit

2. HMI Kits

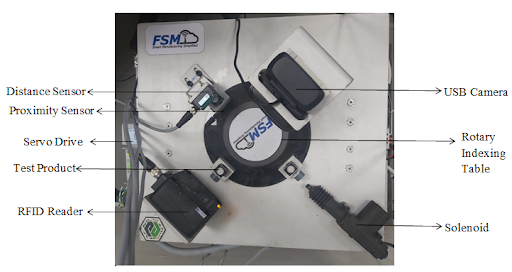

3. Mechanism Kit

Station 1: It has a RFID controller used to read and write the tag values of a product. It communicates with IO Link master (present in PLC trainer kit) and IO link master communicates the data with the PLC. So, RFID operation and use case is demonstrated.

Station 2: This station consists of a distance sensor used to calculate the height or distance of the product. It is a smart sensor and communicates with IO Link master. So, along with the analog value it communicates it’s status to the PLC as well. Verification of product dimension is also demonstrated.

Station 3: This station has a vision camera installed on it. This camera is used for image processing and product testing. Sorting operation is performed using the image processing feature.

Station 4: This station has a solenoid which is directly connected with the digital output of the PLC. Extension and retraction of the solenoid is programmed in the PLC for this operation.

This mechanism kit is used to demonstrate and train motion configuration and programming, Vision System, Smart Sensing, Machine Learning, Augmented Reality.

Programming Kit

HMI Kit